- CLICK HERE FOR INSTALLATION

- CLICK HERE FOR TECHNICAL

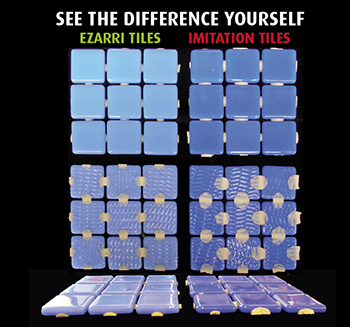

DON'T SETTLE FOR SECOND BEST...CHOOSE EZARRI

Quality control/guarantee

- First to obtain ISO901.200 quality control

- Quality controlled in all aspects of all raw materials to manufacture & dispatch

- Ezarri tiles come with a certificate of guarantee & authenticity

- Round corners mean no sharp edges

Environmentally friendly/sustainable

- 100% Recycled glass used in production

- Ezarri carry ISO14021 quality certificate for effective management

- Support the green building council to promote sustainability in building

Safest backing system

- Proven & safest JointPoint backing. Allows 92% free space for adhesive

- Backing system exceeds the Australian Standards

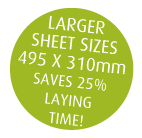

- Save 25% laying time with larger sheets 495 x 310mm – time is money!!!

Diverse in design & colour

Services available

- Screen printed designs

- Custom murals

- Anti-slip tiles available

- 13 unique ranges in over 100 colours

- Suitable for pools, spas, kitchens, bathrooms, indoor/outdoor, commercial/domestic

Ezarri at a Glance

- Screen printed designs

- Custom murals

- Anti-slip tiles available

- 13 unique ranges in over

100 colours - Suitable for pools, spas,

kitchens, bathrooms,

indoor/outdoor,

commercial/domestic

Previously, with the "paper" system, you were required to wait for the concrete to dry in order to be able to remove the paper from the tiles and then carry out the grouting as per normal.

Now, as soon as the panel is fixed, the grouting can be done immediately, as they are not covered with paper, but are joined to each other by the silicone points which avoid this problem, making sheets secure. A real advance in tiling technology!

Points System

About the JointPoint System

The points paneling system is an advantage of the glass mosaic manufactured by EZARRI consisting in pieces that are joined one to another through "silicone points" applied at the reverse side of them, thus forming flexible panels of fixed dimensions easy to adapt to any surface. In this way, just after fixing each panel on the concrete, the filling of joints can be carried out without having to wait for them to dry. That means comfort, efficiency and up to 25% time saving in the laying of the material.

- It is insensitive to humidity

- It is easy to lay out

- Approximate 25% reduced laying time

- Without the inconvenience of having to unstick the paper

- Visual control of the product quality before laying as tile face is immediately visible

- Flexible panel that easily adapts to all types of surfaces

- Panel with fixed dimensions that always keeps its shape

- Total guarantee of getting gripped and fastened to the wall because the pieces are joined to one another by the points

- Easier to lay out creating a better finish

INFORMATION - TILES |

|||||||

Formats |

Weight

/ sq.mt. (Kg) |

Panels

/ sq.mt |

Panel

size |

Pieces

/ panel |

Sq.

mt./box |

Sq.

mt / Pallet |

Weight

/ Pallet |

2.5

x 2.5 cm |

9.6 |

6.5 |

31.5

x 49.5 cm |

12

x 19 |

2 |

96 |

922 |

3.6

x 3.6 cm |

11 |

9 |

33.4

x 33.4 cm. |

9

x 9 |

2 |

108 |

1.188 |

5

x 5 cm |

13.4 |

10.5 |

31.3

x 31.3 cm |

6

x 6 |

2 |

84 |

1.126 |

INFORMATION

- BORDERS |

||||||

Format |

Borders

n† |

Panel

size |

Panels

/ Box |

LM

/ Box |

Weight

/ LM |

LM

/ pallet |

2.5

x 2.5 cm |

1/6 |

36.5

x 18.2 cm |

34 |

12.4 |

1.75 |

669.6 |

3.6

x 3.6 cm |

1/2 |

29.6

x 25.8 cm |

18 |

5.33 |

2,84 |

287.8 |

3.6

x 3.6 cm |

7/8 |

29.6

x 14.8 cm |

36 |

10,64 |

1.63 |

574.5 |

WATER ABSORPTION (UNE EN 1SO 10545-3). Mosaics are dried up to a constant weight, immersed in boiling water and then kept there for 2 hours, leaving them to cool down in the water for 4 hours. It is determined if there has been a variation in the weight after the test so as to check whether there is or not a water absorption. Results of EZARRI mosaics: E = O,1%. Classification of the tiles: E<3% Low water absorption. ================= 3%< E < 10% Average water absorption. ===================== E>10% High water absorption. |

||||||||||||||||||||

| ABRASION

RESISTANCE (UNE EN ISO 10545-7). The method is based on the rotation of an abrasive load (steel balls, aluminium oxide and water) on the mosaic surface and the wearing evaluation by a visual comparison of the specimen submitted to tests with mosaics not submitted to tests. Classification 2 was obtained. Defects were visible at 600 revolutions. (Scale of results 0 to 5 from lower resistance to higher resistance). |

||||||||||||||||||||

| FREEZE

RESISTANCE (UNE EN ISO 10545-12). Mosaics are submitted to 100 freezing-unfreezing cycles in the following way: the mosaics temperature is lowered until –5† for 15 minutes, later they are immersed until reaching a +5† temperature and they are kept there for other 15 minutes. The water absorption is determined and a visual examination is carried out in order to watch any damage in both the mosaic face and edges. No mosaic showed any defects after carrying out the test.. |

||||||||||||||||||||

| CHEMICAL

RESISTANCE (UNE EN ISO 10545-13). Mosaics are submitted to the following solutions: – Domestic cleaning products – Swimming-pool salts – Acids and bases: weak and strong concentrations And they are classified depending on the impact caused on the mosaics by the different agents, being Ezarri classified in the best of the possible positions. |

||||||||||||||||||||

|

||||||||||||||||||||

| RESISTANCE

TO STAINS (UNE EN ISO 10545-14). Mosaics are submitted to different agents causing stains and some cleaning procedures from the most simple to the most complicated are established. The test result determines 5 types of tiles depending on their capacity to make a specific kind of staining agent disappear. Ezarri’s mosaics have the best possible classification (5) with regard to each of the tested staining agents. |

||||||||||||||||||||

|

||||||||||||||||||||

| SCRATCH

HARDNESS (UNE 67101). It is carried out according to the Mohe scale, by rubbing with the hand certain materials of known hardness on the mosaic surface. Result obtained: 5 (Results scale 0 to 10, from the highest to the lowest resistance). |

||||||||||||||||||||

ACCELERATED

AGING.

|

||||||||||||||||||||